Decision Making!

As humans we like to think of our self as rational and logical. When one studies decision making it is a varied and complex topic. Emotional decisions can be taught to a human in many different methods that go far beyond the scope I wish to address.

When developing a decision in a group the most important aspect, fundamental to success is! THERE IS NOTHING BAD ABOUT BEING WRONG, IN FACT IT IS BENEFICAL! FOR ONE LEARNS!

It seems so simple, but very difficult to make it happen as a group ! For most of the ideas will be shot down!

In a competitive environment these seems counterintuitive! Just recently another study showed, by Google the most productive teams where the non judgmental ones! Reserving emotional comments in a team decision process is most important! I have seen business despite smart marketing and high skill, literally destroy themselves, due to the emotional input of a powerful individual in the group. In other words, make very dumb decisions!

This is probably the simplest way I can explain the emotional part of decision process, but in business and project management, it is also mathematical.

I will start with weighing out simple two options problem one sees often in construction. Here is simple graphical outline to involve stake holder in using stair versus ramp.

Building Stair versus Ramp.

|

Less expensive |

Steeper less run |

|

|

More space needed |

|

Can use wheeled tools |

Less slippery |

|

|

Expected wheeled tool use 40 % |

|

Another stair available |

|

|

Expected wheeled tool use 40 % Another stair available Notice the partial use like 40%; it makes the decision process more interesting. In math one would call it weight, variable or constraint. One runs into these problems often in construction for nothing stays the same. One can also attach a mathematical quantity to importance (how important is the wheeled use of the ramp). To make mathematical analysis work! One needs accurate data time measurement helps use of a data base helps, accounting data is also very useful. For example, steel beams need to be wheeled in the importance of the ramp may become 100%. One is faced with decision making like this all the time in construction change one variable and what was cost effective one day becomes more expensive the next. Using the design spiral, and W5 essential with mathematical analysis.

Mathematical Analysis!

I will use this exaggerated physical situation in order to highlighter several aspects!. The problem presented! Tile laying a driveway area is 2000 square feet. The job needs to be finished in one day. Asses the technical feasibility of the job?

In this instance a team of two tile layers plus one laborer lay 100 square feet per day. The laborer can mix mud for one day in one hour, the cement mixer can mix mud for three teams in one hour.

This is typical data that contractors know taken from time sheets of the employees!

Lets look at the problem using a minimization equation!

x = Team of tile layers needed

a = 2 tile layers / 100 square feet per day

b = Laborer per day mud mixing

c = cement mixer

x( a (100square feet per day)) + 1/8 b (100square feet per day) - 2000 (square feet per day)= 0

Result x= 40 tile layers

b= 3 laborers to mix mud

c = 7 cement mixer

Lets look at the logistical problems first!

A tile layer will say not possible. For every tile layer needs a lay out line to start from so normally one would max out on two teams for one would start from center line and work away from it!

Next consideration is there enough space for all the tile layers to move? Are the tiles close by, within the work area of each team.

Another problem 40 people show up and all are waiting for the mud to mixed ,for no tile can be laid until the mud is mixed. The risk of something going wrong has increased by a factor of 40. The laborers are also a problem given the number of laborers they can only mix this amount of mud in one day, so some tile layers would get the mud to lay tiles at the end of day. In other words they would be waiting most of the day!

The effect would be lots of people on the job most would not be able to work, expenses way up, production way down! On the workers the psychological impact would also be severe trying to look busy and get something done.

The conclusion! Linear minimization equations do not work in this instance for the work is sequentially time dependent!

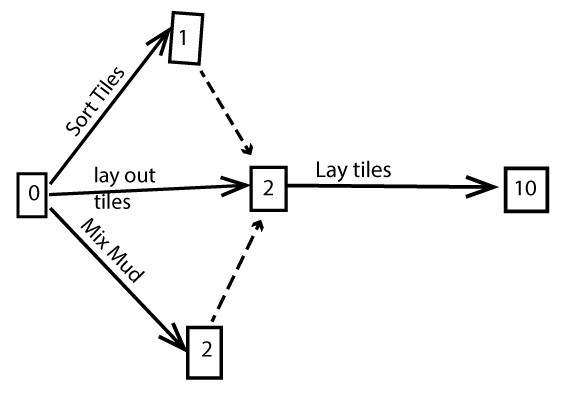

In this instance will show the the use of a simplified critical path method to calculate the optimum possible outcome.

I will show a formal version of such an algorithm in excel. I kept it simple to show two important aspects.

If one wishes to maximize the construction speed there is usually a component that will take longer than normal. In this instance tile lay out will take considerable time for one needs to locate the initial row of tiles exactly so many individual teams can work together. for clarity I left out the 40 trades but only focused on tasks. One still needs 40 tile layers but how many laborers do are needed for each team has one laborer for 8 hrs but not a clear description what they actually do. one knows for certain from inspection they mix mud, and we form assessment of the tasks the tiles need sorting all those task are done early now before tile laying starts, But are they also laying tile? Experience would dictate they do! But no idea how much time spent for no time analysis took place. Since one is using data from the time sheets. So here comes an important part one needs to asses how much float one needs. In other words how much man power is available on short notice if needed.

Float "Manpower availability on short notice, a important aspect in an time constraint environment"

In this instance one has to guess the number of laborers or better extra tile layers needed. for one may need two or three teams on short notice.

The logistical task's are going to be the biggest constraints in dealing with such a short time for installation.

The path method is useful in identifying aspects in the construction technique one wishes to analyze. For example here one can see the tile laying time is 8hrs. one can do a cost benefit analysis in this area see how much faster it can be done. in other words, use time measurement analysis.

Critical path analysis is also used in timing subcontractor on a project. For more complex timing analysis Microsoft Project is used it uses these principles in its calculating engine.

This graphical technique and using excel is already immensely powerful and I like the flexibility of designing my own approach to utilizing this algorithm.